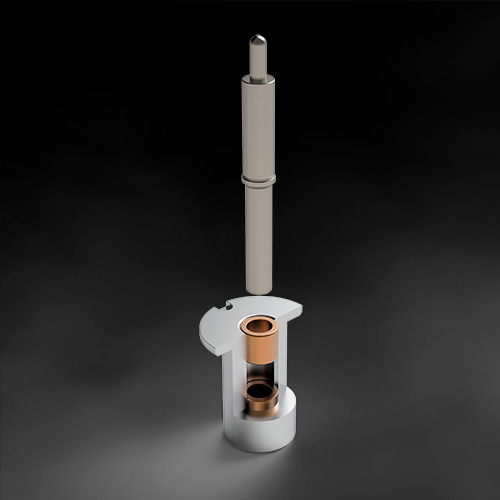

Acoustic Signature DTD® Bearing:

A class of its own!

The bearing is the heart of every turntable. Although the bearing design is of such great importance, its development – from the view of physics – is often characterized by imprecise to wrong approaches. Any conventional bearing that is confronted with a heavier platter is extremely sensitive in terms of handling. It also faces a mechanical challenge that is mainly to be found in the contact area of the thrust plate and bearing ball. In other words: the combination of the high platter weight and the very small ball surface causes an enormous pressure in the very small contact area, which simply pushes the lubricating oil away.

The result: too much friction, too much noise, too much vibration and rapid wear. Analogists seeking salvation in an ‘inverted bearing’ are misguided by a marketing trick: the main source of noise within a conventional bearing design is located at the pivot point of the platter axis and the thrust plate, about 4 inches away from the record. By inverting the bearing, this noise source is taken closer to the platter direct below the vinyl surface and thus into the activity area of the cartridge – definitely not a good idea. Moreover, this ‘reversal’ causes a veritable lubrication problem thanks to gravity: the oil is floating away at the contact surface.

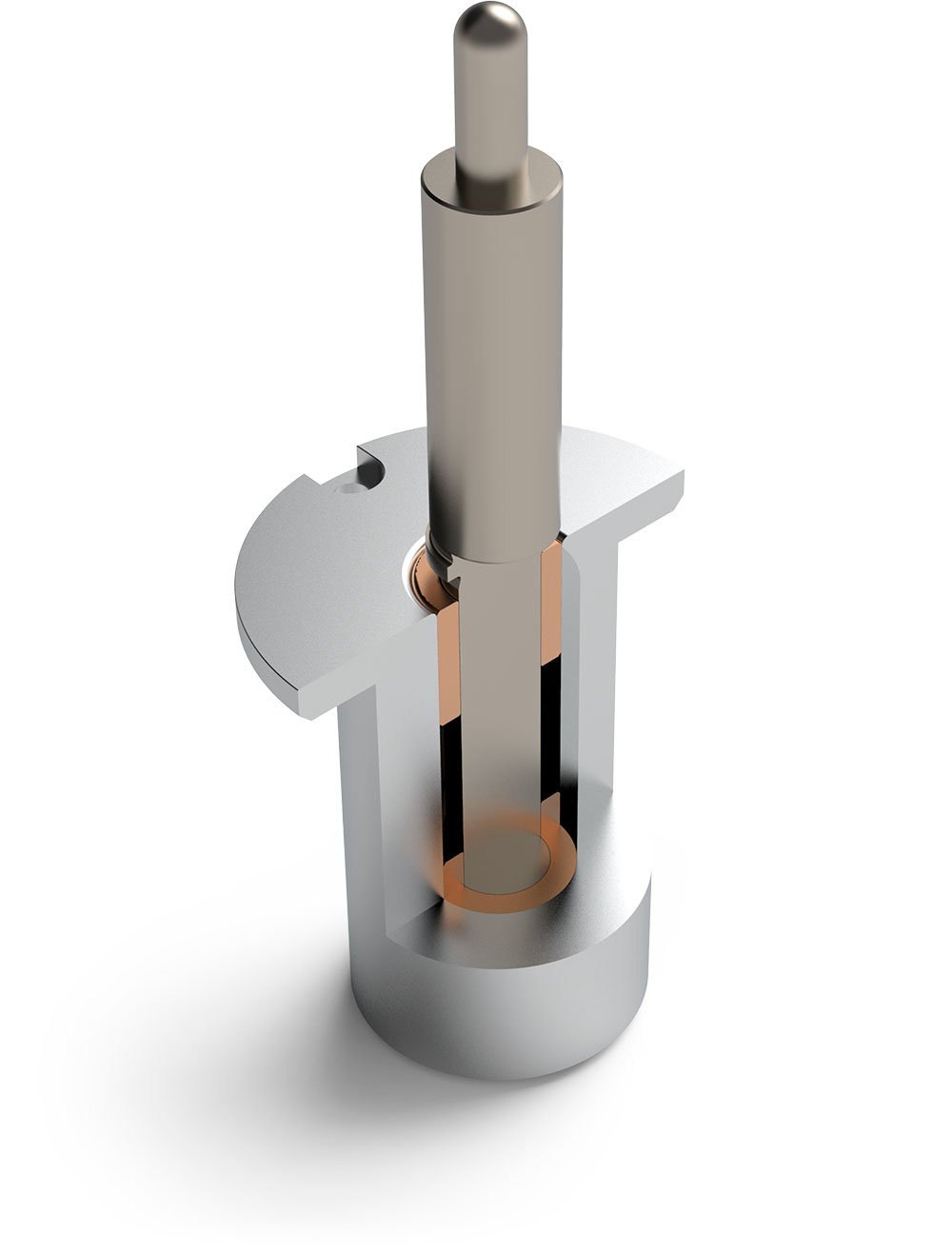

When we introduced our Tidorfolon® Bearing in 1997, we immediately received enthusiastic feedback: made of a very innovative material combination, the Tidorfolon® Bearing was hard enough not to be affected by the high mass of the platter and soft enough to withstand even a ‘dropped’ plate without any damage. Another highlight: the material mix is able to absorb the oil like a sponge and release it when needed. In other words: the oil cannot be pushed away; the lubrication is always there when needed. Refill oil? Not necessary! Replenishment? Not necessary! Maintenance? Not necessary! Audiophiles and the specialist media worldwide have celebrated this extremely robust and low-noise bearing as a benchmark-setting innovation.

What’s the improvement of the DTD® Bearing: we succeeded in reducing the already imperceptible noise level caused by mechanical movement even further, thus making the famous background when listening to music even blacker. We achieved this by using newly developed sinter-bushes that can store three times the amount of lubricating oil. The design of the spindle was also put to the test. Our aim was to minimize its surface contact and the resulting noise. So, a vacuum-hardened stainless-steel spindle is grinded precisely and then subjected to an elaborate plasma coating. The result is a spindle with a diamond-like surface coating that competes with the hardest material on earth and reduces the friction coefficient by 60 percent!

The Dura Turn Diamond® Bearing is a super-rigid and virtually ‘indestructible’ bearing that creates the best possible conditions for absolute high-end sound and sets news benchmark in terms of maintenance, low noise and service life – backed by a 15-years warranty. The DTD® Bearing is manufactured for each turntable in the Acoustic Signature NEO series in an individual version adapted to the respective turntable.

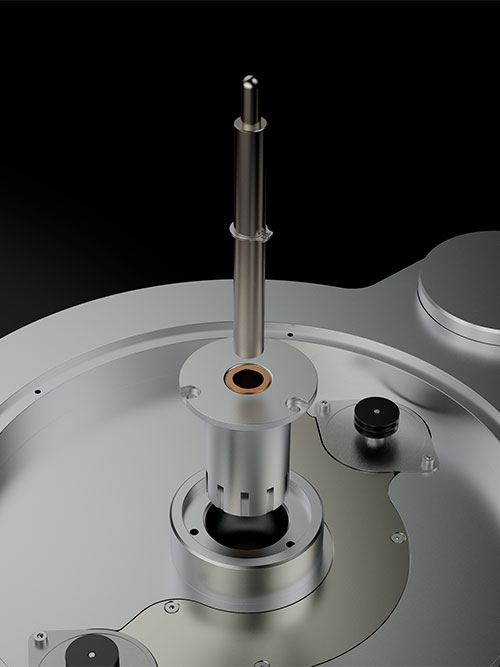

Selected bearings

Bearings in the manufacture of Acoustic Signature before their assembly into the turntables. The bearings are made of a special material combination and are extremely sturdy and run revolutionary quiet.

Bearing evolution

The Acoustic Signature Tidorfolon® Bearing inaugurated in 1997 and changed the analogue world. The further optimized Dura Turn Diamond® Bearing was released in 2020 and is implemented in all turntables of the new NEO-Series.

Manufacturing in Germany

All of our products are produced in the city of Suessen in Germany with manual craftmanship. They are individually finetuned for a maximum of performance.

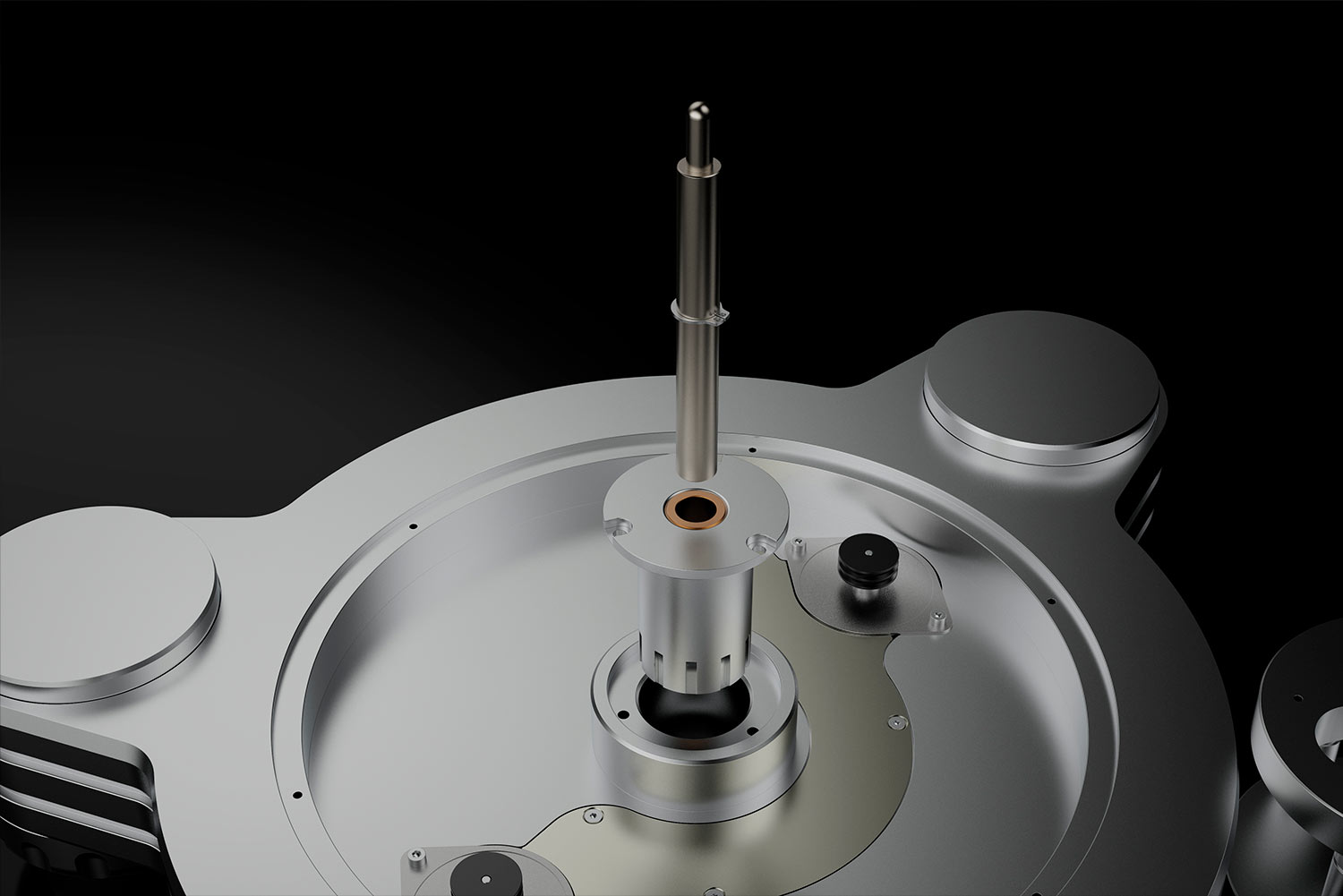

DTD® Bearing on the Maximus NEO

We are so convinced of the performance of our newly developed Dura Turn Diamond® Bearing, that we are implementing it consequently into all of our NEO-Series turntables. Starting with the “smallest” in the new family, the Maximus NEO, each NEO turntable benefits by the new bearing.